At Dutch Poultry Tech, we innovate to create practical solutions for poultry processors worldwide. Based in the Netherlands, we design and manufacture standardized, pre-fab poultry processing systems. Our equipment is intentionally designed to be easy to install, -operate, and -maintain, all with full technical training and without the need for specialized external (expensive) engineers. Our core mission is to make practical processing accessible to producers everywhere.

We observe that the industry’s obsession with massive, high-speed lines often comes with serious risks. We see the major drawback: a single breakdown can affect production for hours, even days, resulting in thousands in lost revenue.

A Smarter, More Resilient System

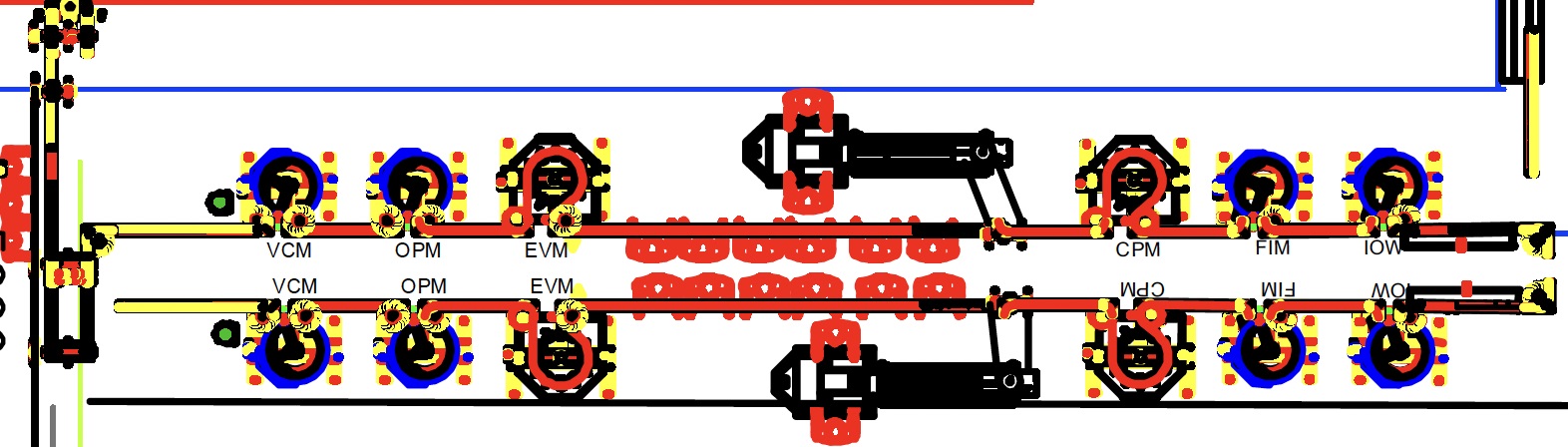

That’s why Dutch Poultry Tech promotes a fundamentally different approach: distributed processing capacity.

Instead of relying on one high-speed line (e.g., 13,000 birds per hour), we supply multiple, compact, pre-fab, fully automated lines that are floor-mounted and easy to manage. A typical setup uses three lines, each running at a more moderate 6,500 bph. An intelligent weight distribution system splits the load approximately in thirds, ensuring maximum efficiency.

Advantages?:

- Less Vulnerability: If one line goes down, the other two can quickly compensate, ensuring minimal disruption and little to no production loss.

- Flexible Maintenance: Routine (even complex) maintenance can be performed on a single line during normal operating hours without impacting full production. This eliminates costly, night or weekend shifts.

- Simplified Management: Our standardized designs lead to lower overall costs, simpler spare-part management, and easier operation

Our approach is about working smarter, safer, and more resiliently, building systems that fit your business instead of forcing your business to fit an overly complex and inflexible system.

For more information:-www.dutch-poultry-tech.com