Are you ready to transform your tuna processing operations and stay ahead in the market? Traditional tuna processing involves cooking the fish and manually disassembling it to extract the meat for canned tuna. This method relies heavily on scarce labor, fails to maximize the potential value of by-product raw materials, and keeps operating costs high.

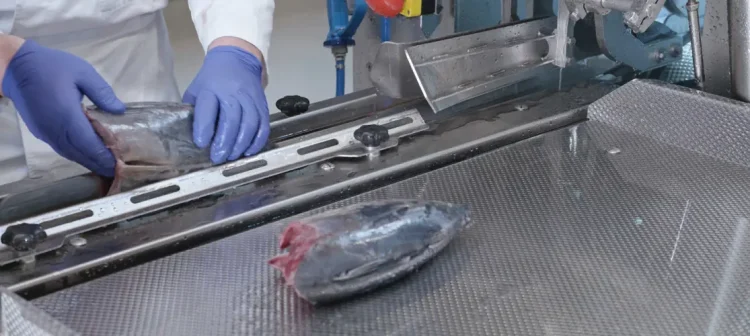

We are transforming tuna processing by introducing innovative techniques such as deheading and filleting the fish before cooking with the Curio Fish Filleting Machine and Curio Heading Machine, effectively reducing labor requirements, broadening your product range with high-value by-products, and cutting operational costs.

Increasing profitability in more ways than one

Increasing profitability in more ways than oneOur innovative approach revolutionizes tuna processing, enhancing profitability by offering a wide range of finished and by-products. From whole white loin sold raw or cooked for canning to shelf-stable products, frozen raw portions, and minced meat, each product maximizes the value of the fish. Valuable by-products like fish oils, collagen, pet food, and fish meal further contribute to this value. Moreover, this method conserves energy by reducing the cooking time required for processed tuna, ensuring operational efficiency alongside profitability.

Elevating production efficiency

With precision and ease, our advanced machines effortlessly handle skipjack and yellowfin tuna weighing up to 9 kg, extracting maximum value from your raw materials.

Automating the tuna filleting and deheading process reduces labor reliance to just one operator and eliminates human error, ensuring unmatched reliability and consistency.This not only increases productivity and throughput but also reduces costly mistakes, ultimately enhancing profitability and operational success.

The revolution is here

Embrace the future of tuna processing with the Curio Fish Filleting Machine and Curio Heading Machine and gain the competitive edge your business needs. Experience the transformative benefits of automation and elevate your production to new heights.

The Curio Heading Machine effortlessly and accurately removes the heads of skipjack and yellowfin tuna weighing up to 9 kg, increasing operational efficiency and profitability. Its advanced technology ensures precise cutting that maximizes the value of each fish while minimizing waste. With the ability to dehead up to 25 fish per minute using only one operator, this machine significantly reduces your reliance on labor and enhances processing speed.Automating the deheading process of uncooked tuna opens up opportunities to produce valuable by-products from the raw material. For example, the fish’s collarbone can be utilized for minced meat, while the remainder of the head can be transformed into fish meal.

The robust design simplifies cleaning while easy access to internal safeguards streamlines maintenance, minimizing downtime. Additionally, the automatic lubrication system enhances reliability and safety, reducing the need for repairs.

Curio Fish Filleting Machine

The Curio Fish Filleting Machine requires only one operator to efficiently and automatically fillet skipjack and yellowfin tuna weighing up to 9kg. This significantly decreases reliance on labor, waste, and human error linked with manual processing while achieving a high throughput of up to 25 fish per minute and maintaining exceptional quality.Its adaptable design, with adjustable frames, accommodates fish sizes from 400g to 9kg, ensuring flexibility and high yields.

With four versions available and conversion kits to expand processing capabilities, it guarantees a long lifespan for your investment.Operating the machine is simple, whether onshore or aboard vessels, with mechanical adjustments available to optimize yield and performance. Maintenance and cleaning are straightforward, thanks to its robust construction and quality materials, which ensure longevity and minimal upkeep.

Are you ready to increase your profitability, maximize your raw material utilization and minimize your dependance on labor in your business? Register your contact information below, and a tuna processing expert will get in touch to discuss your needs and explore how we can collaborate to transform tuna processing together.